When we talk of industrial peristaltic pumps, , we find that there are 2 types of pumps, depending on how the hose is compressed: Roller pumps and shoe pumps. Each technology has its own advantages and drawbacks.

For more difficult applications, we tend to use pumps with shoes, which are much stronger than pumps that use rollers. This way, the components of the pump last longer.

Pumps with rollers are usually associated to to simple applications that only require low pressures. The designs for these pumps tend to be weak and simple, which means they are very limited and useful only for undemanding applications.

However, Boyser peristaltic pumps with rollers have significant advantages compared to other roller pumps on the market, and even compared to the more robust pumps with shoes. The lack of friction between the hose and the rollers gives it a series of very interesting advantages:

- Ease of operation: Due to the lack of friction, the torque needed to operate roller pumps is much lower than for shoe pumps, which means they can be operated much more gently and it is easier to use the frequency converter to adjust their speed.

- Ease of maintenance: Roller pumps do not need to be flooded with lubricant (because of the lack of friction), and they can use a smaller rotor, which makes the process of changing the tube much easier.

- Energy saving: The friction produced by shoe pumps is a needless waste of energy. Roller pumps, which don’t generate friction, can do the same amount of work as shoe pumps while saving 30% of energy.

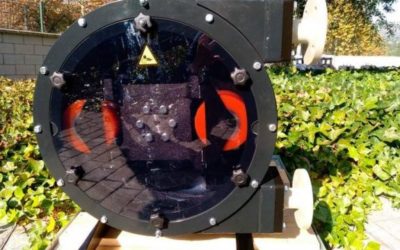

In order to make the most of the advantages offered by roller pumps, but also reduce their limitations, Boyser Pumps has created the FMP roller pump series. These pumps are extremely strong roller pumps, similar to shoe pumps in this regard, but retaining the advantages of roller pumps.

The main advantages of the FMP peristaltic pumps with rollers are:

- The rollers used in the Boyser FMP-series peristaltic pumps incorporate oversized bearings with a useful life of more than 100,000 hours of operation.

- In the larger models (FMP-50B, FMP-60B and FMP-70B), the rollers are extra large and made from polyurethane, thereby achieving a larger compression surface on the hose, significantly improving the lifetime of the hose.

- It includes an oversized shaft and integrated bearings, which ensure full support of large radial loads produced when the hose is compressed. The life of these rollers is over 100,000 working hours.

- They use the most secure patented connection system, with a double conical ring, which ensures a correct seal between the hose and the connections under any circumstance.

Thus, we are dealing with pumps that are completely different from traditional roller pumps. We are dealing with a new type of peristaltic pump: Very strong roller pumps, for the most demanding applications, and making the most of the advantages of roller technology.

Undoubtedly they are THE BEST PERISTALTIC ROLLER PUMPS IN THE WORLD!