Dosing diaphragm pumps are excellent for dosing a wide range of products. Their accuracy and electronics mean that they are the main technology used for dosing liquids.

However, due to the design of design of these types of pumps, there are applications where problems arise. These types of pumps have inlet and discharge valves, as well as some other additional elements such as foot and counter-pressure valves.

In some applications, the fact that these valves exist can be a problem. When we pump products with solids, for example, there is a risk of the valves not closing correctly or becoming blocked, which would cause them to not dose correctly.

In other applications where the product has a certain viscosity, the valves do not work correctly and special valves with springs may be required, making the pump more expensive and potentially causing problems of accuracy and operation.

Other products that generate problems for this type of pump are products that generate gases (such as sodium hypochlorite). Diaphragm dosing pumps are not able to pump these gases, and the pump ends up empty and not working.

Lastly, this type of pump needs foot and counter-pressure valves. The foot valve is needed because the pump must always be flooded in order to work (it is unable to evacuate air), whereas the counter-pressure valve is used to control the discharge pressure. Diaphragm dosing pumps always need to work at the same back pressure, since they provide different flow rates at different pressures.

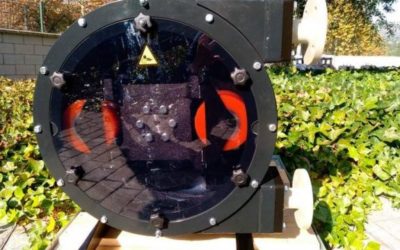

A perfect solution for these types of troublesome applications is Boyser’s industrial peristaltic pump.

THE MAIN ADVANTAGES OF BOYSER PERISTALTC PUMPS COMPARED TO DOSING DIAPHRAGM PUMPS

The main advantages are:

- They don’t need valves. Products with solids or viscous products are not a problem. Boyser peristaltic pumps can pump and dose products with 80% solids, and products with a viscosity of up to 100,000 cPs.

- They don’t need foot or counter-pressure valves. Peristaltic pumps are able to suction products while running dry without any problem. They do not need to be flooded to operate normally. They also do not require counter-pressure valves, since they can dose constantly at different pressures, without affecting the flow rate (it is the perfect volumetric pump, always displacing the same amount on each revolution, regardless of the working pressure).

- It is able to pump gases as well as liquids. As a consequence, it can evacuate the gases that some products (such as sodium hypochlorite) generate without any problems.

Thus, Boyser peristaltic pumps are an excellent alternative to dosing diaphragm pumps for the following dosing applications:

- Dosing products that contain solids.

- Dosing viscous products.

- Dosing products that generate gases.

- Dosing with high suction levels.

- Dosing with variable discharge pressures.