Bombas Boyser SL Spanish peristaltic pumps manufacturer and industrial lobe pumps bombas peristálticas y bombas lobulares industriales, celebrates its first 25 years of life at the end of this 2018.

At the beginning of the 1990s, in 1993, our General Manager, Joan Jofresa, founded the company in a small workshop in Caldes de Montbui (Barcelona) and began its journey to this day, placing it among the most important in the world manufacturing both technologies. Belonging since 2009 to the German multinational Prominent, we lead the worldwide sector of positive displacement pumps.

With a range of 20 peristaltic pumps, one of the most complete in the market, we cover a wide spectrum of flow rates for different industrial applications, being able to treat the most corrosive, abrasive and viscous fluids thus providing solutions to problems that the industry can only solve with peristaltic or lobular technology. Very specific products for very specific solutions that could hardly be treated with other technologies having a capital cost and operational cost ratio as good – unbeatable in fact – as the pumps we manufacture. That is the most special feature of our product: the uniqueness of it. Hardly if a peristaltic pump or lobular pump does not solve a problem, other technologies may.

LEARN ABOUT THE ADVANTAGES OF OUR INDUSTRIAL PUMPS

In general, the main advantages of our technology are:

- Dosing and transfer of high precision for products such as sodium bisulfite, hypochlorite, brine, glue, titanium oxide, iron chloride, etc.

- 100% flow rate proportional to the speed: no return

- It is reversible: it works indistinctly in two directions

- Can vacuum in vacuum: self-priming

- Very resistant to abrasive and corrosive fluids

- Perfect for high density products

- The only component that suffers wear is the tube since the rest of the pump is not in contact with the fluid

- Cost of the tube does not usually represent more than 10% of the total pump

- Wide variety of tubes, with different manufacturing materials and varied diameters.

- With sensitive products, the pump behaves very lightly and the passage of the fluid occurs smoothly. Minimal losses in the fluid compared to other more aggressive products

- Low starting torque

- Very wide working frequency range (3-75Hz)

- No mechanical seals

- No moving parts

THE DIFFERENCE OF BOYSER, PERISTALTIC AND LOBULAR PUMPS MANUFACTURER, COMPARED TO ITS COMPETITORS

- 25 years’ experience with the product focused on it: we are specialists in peristaltic pumps because it is our “core business”

- Robust and compact designs: durable pumps

- Wide range of pumps to cover all the flows

- Fast delivery times

- Competitive price

- Roller and shoe technology: we manufacture both.

OUR PRODUCTS IN PERISTALTIC PUMPS AND LOBE PUMPS

Our range is formed by these two families of products:

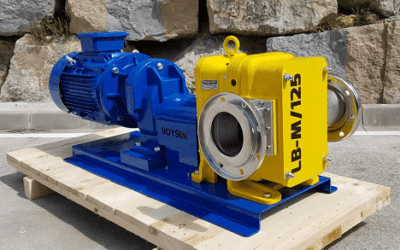

Industrial Lobe Pumps of rubberized rotors for working pressures of up to 10 bar.. Flow rates from 10 to 120 m3 / h, versions in stainless steel AISI-420 or steel AISI-316.

Sanitary lobe pumps, with all the parts in contact with the fluid manufactured in stainless steel AISI-316L. Flow rates from 500 to 40,000 l / h and working pressures up to 12 bar. There is also a hygienic version with EHDEG certification.

Existe asimismo una versión higiénica con certificación EHDEG.

The main advantages of these pumps are:

- Compactness

- Very low maintenance cost

- Can work dry for a certain period of time

- Very low electrical consumption

- Reversible

- Self-priming

- Can work with fluids sensitive to breakage (polymers, for example)

- It allows to pump a high concentration of solids

- Wear resistant

- They can treat high viscosity products

Our product range consists of four series. We will choose the most appropriate one according to the needs of the client and the application to be treated.

AMP Seires: Industrial peristaltic pumps with reinforced rubber hose for working pressures up to 8 bar. Flow rates from 10 to 1200 lph.

FMP Series: Industrial peristaltic pumps with reinforced rubber hose for working pressures of up to 8 bar.Medium and high flows, up to 44 m3 / h.

RBT Series: Industrial peristaltic pumps with reinforced rubber hose for working pressures up to 15 bar.Flows from 100 to 36,000 l / h.

DSM Series: dosing or transfer of fluids in small flow and low pressure.

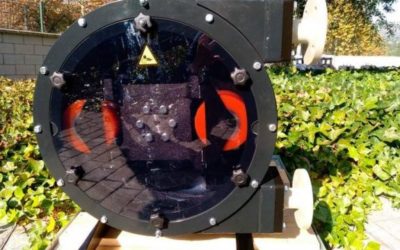

Flexodamp: Pulsation damper for continuous flow, which allows the use of measurement systems such as flow meters or pressure switches.

FIELDS OF APPLICATION OF INDUSTRIAL PUMPS BOYSER

Boyser lobe pumps work in fields as diverse as the agri-food industry, pharmaceutical industry, paper industry, etc.

Present in sectors such as mining (one of the most representative sectors), petrochemical, food, etc., we increase year after year the range of applications we dominate thanks to our experience of more than two decades and our team of application engineers. We discover new market niches where our pumps replace traditional technologies, providing advantages in the maintenance of the equipment and increasing the economic benefit for the end user. More and more industries are using the peristaltic pump because they know the advantages of it. Definitely, the maintenance costs are very low in comparison to the operational cost of other technologies and the costs related to the problems in the pumping systems that companies suffer when there is premature wear of components, breakages due to fatigue, bad design, envelope or infra dimensioning of the product, ignorance of the application, etc.

Likewise, the range of industrial lobe pumps, with almost six years of life, is ideal for applications where for various reasons the peristalsis is not the technology that best fits at the level of Capex and Opex equilibrium: high flow rates, very viscous fluids, etc.

We have a division specialized in oenology pumps with more than 500 end customers in the world, using our pumps through our distributors or OEM’s in the sector.

We work very hard to continue being leaders in the next years with new designs to expand the range and thus give, if possible, more options to our customers to improve their processes by reducing costs thanks to our improvements.

Currently, we are present in more than 80 countries through a wide network of distributors specialized in our product. You can contact us through them, calling us at 93 844 77 78 or sending an email to info@bombasboyser.com